Visualization and control of the ripening process at the Dutch company Van der Lem in the town of Uitgeest

June 6, 2014 | Reliance SCADA

Van der Lem is a Dutch company specializing in the packaging, distribution, and sale of fruits and vegetables. The company's headquarters and warehouse with rooms for ripening bananas are located in Uitgeest, North Holland. The distribution of fruits and vegetables is provided by modern and fully-equipped trucks.

Control system

In the company's warehouse, a system designed to visualize and control the ripening process in 7 out of a total of 28 ripening rooms was installed. The system was implemented by the Dutch company De Laat Koudetechniek.

Each ripening room is equipped with a cooling system, which consists of a fan and evaporator. Cold water is used as a coolant during the process. The cold water is cooled based on ammonia (NH3) cooling in a 2MW cooling system.

NH3 compressors

The system controls the air circulation in the ripening rooms. This allows bananas to ripen equally. To control the banana ripening process, ethylene (C2H4) of a specific concentration is released into a ripening room. As a result, a mixture is created to start the ripening process. The ethylene is held in a tank located in a central unit. The tank is connected to all ripening rooms.

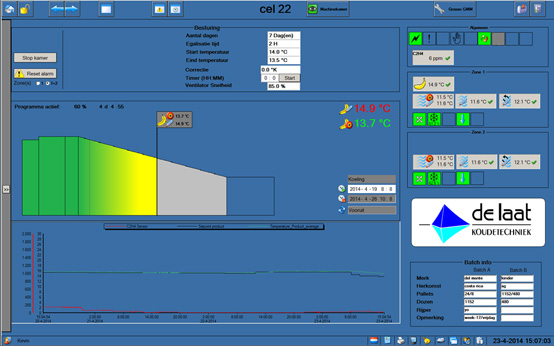

To control and visualize the process of banana ripening, the Reliance SCADA/HMI system is used. Reliance is installed on the fruit storage main office's computer. The Reliance system acquires the process data from Siemens SIMATIC S7-300 and S7-1200 PLCs. Reliance and the PLCs communicate via an OPC server. All tags defined through the Reliance system are structured.

Special features for this project are:

- All is done in templates and structures

- The whole project is based on Windows themes (all components' colors can be changed to the liking of the user)

- Dynamic touchscreen panel integration through the ActiveX Container component

- Dynamic integration of Web servers for NH3 compressor maintenance monitors

- The special internal tag named ActiveAlarmsInDevice is used to create an iOS-like badge displaying the number of active alarms in a room

- All databases are stored in separate folders as safeguards while changing the project files

- Automatic project update is used (the availability of a new version of the Reliance project is checked each time the project is started)

NH3 heat exchanger

Thanks to a large number of well-arranged visualization screens, the warehouse operating personnel can view and control:

- The ripening process in a ripening room including individual ripening stages

- The cooling process in each ripening room by controlling the evaporators and fans

- The air circulation process in the ripening rooms

- The 2MW cooling system

- The ethylene-releasing and dosing process

Examples of visualization windows

The overview window

Visualization of the banana ripening process

Temperature settings for a ripening room

Detailed settings for a ripening room

Try the Reliance SCADA/HMI system

Try the Reliance SCADA/HMI system on several example projects or download the installer of the trial version for free.

Country

Netherlands

Title

Visualization and control of the ripening process at the Dutch company Van der Lem in the town of Uitgeest

Implemented by

De Laat Koudetechniek B.V.

Year

2013–2014

Control system

Siemens SIMATIC S7-1200

Siemens SIMATIC S7-300

SCADA software

1 x Reliance 4 Control with 5,000 data points